We are developers of

high-end industrial

electronics.

We will develop it

also for you.

We specialize in the development of

embedded hardware

and systems.

We have been developing embedded hardware and systems since 2000, when our company was founded as a subsidiary of the German company Kontron Elektronik GmbH. Between 2000 and 2021, we acted as a development center for our parent company as well as for other members of the Kontron group, especially in the USA, Canada and France. At the turn of 2021 / 2022 we became independent and today we are an independent purely Czech company. We continue to develop embedded hardware and systems. We continue to work closely with our former parent company as a "Certified Design Partner" and as an "Authorized Business Partner".

What we can offer to you

What specifically can we

help you with?

We can supply or design and develop industrial hardware or the entire system according to your specifications. Or we can supply any related service separately.

Overall, we offer a wide range of services in the development, modification, testing and production of embedded systems and hardware. This enables us to improve your product development process, reduce costs, speed time to market and achieve your business goals better and faster.

EMBEDDED HARDWARE DEVELOPMENT

EMBEDDED SYSTEMS DEVELOPMENT

More about the service EMBEDDED SYSTEMS DEVELOPMENTVERIFICATION SERVICES

Our

most important technologies

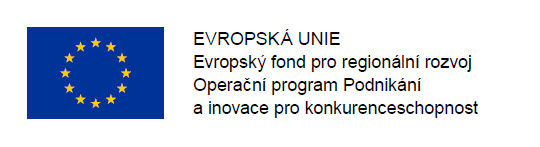

chamber

chambers

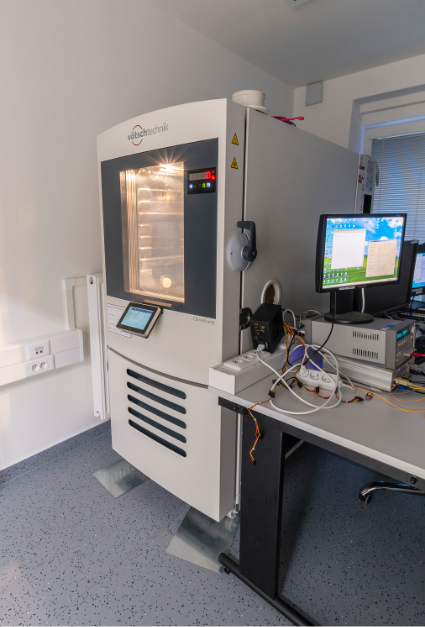

laser

scanner

Our team

Hire us

We will help you

and your product to the world.

Teslova 1120/1

301 00 Plzeň

Czech Republic

VAT ID: CZ25241494

Bank connection CZK

account: 123-6158210267/0100

IBAN: CZ2601000001236158210267

BIC/SWIFT = KOMBCZPPXXX

Bank connection EUR

account: 123-6158220297/0100

IBAN: CZ4001000001236158220297

BIC/SWIFT = KOMBCZPPXXX

Teslova 1120/1

301 00 Plzeň

Czech Republic

VAT ID: CZ25241494

Bank connection CZK

account: 123-6158210267/0100

IBAN: CZ2601000001236158210267

BIC/SWIFT = KOMBCZPPXXX

Bank connection EUR

account: 123-6158220297/0100

IBAN: CZ4001000001236158220297

BIC/SWIFT = KOMBCZPPXXX

Více info zde